Struggling to find a reliable tire valve supplier in China? A wrong choice can cost you money and your reputation. I will help you navigate the market and choose wisely.

Finding a top tire valve manufacturer in China means looking in the right places. The best suppliers are concentrated in the Zhejiang and Jiangsu provinces, known for high-quality production. It's crucial to verify their certifications, material quality, and testing processes to ensure you get a reliable product.

I've been exporting tire valves for over 14 years. I've seen firsthand what separates a great supplier from a bad one. Many of my customers, like Peter from South Africa, rely on me to source consistent, high-quality parts. They can't afford failures. Let me walk you through what I've learned, so you can make the best decision for your business. This is about finding a partner, not just a parts list.

Why does the manufacturing region matter so much?

Have you ever ordered parts from a new region to save money, only to face quality issues? This gamble can be costly. The location of your supplier matters more than you think.

The location of a tire valve factory in China is a huge indicator of quality. Zhejiang and Jiangsu provinces are the heartlands of quality auto parts manufacturing. Factories here have better technology and skilled workers. Other areas, like Hebei, often compete on price alone, which can lead to compromises.

I've spent years building relationships with factories across China. The difference between regions is not just a small detail; it's fundamental to the product you receive.

The Zhejiang & Jiangsu Advantage

These two provinces are home to what I call "industrial clusters1." This means all the related suppliers are nearby. The raw material suppliers, the rubber experts, the brass machining shops—they are all in the same area. This creates a competitive environment that pushes quality up. Factories here, like my own in Ningbo, Zhejiang, have access to the best materials and a workforce that has been making auto parts for generations. They understand the standards required for export markets in South America and South Africa.

The Hebei Gamble

On the other hand, you have regions like Hebei. Factories there often attract buyers with incredibly low prices. But I've learned that you get what you pay for. A few years ago, a potential client asked me to match a price from a Hebei factory. I sourced a sample from that factory to compare. The brass was thinner, and the rubber felt brittle. It wouldn't have passed our standard air leakage tests. Cheaper materials and less stringent quality control are common ways they cut costs. For a critical part like a tire valve, this is a risk not worth taking.

Regional Quality at a Glance

| Feature | Zhejiang & Jiangsu | Hebei |

|---|---|---|

| Quality Control | High & Consistent | Inconsistent |

| Material Sourcing | Premium (e.g., 62# Brass) | Lower Grade |

| Worker Skill | Experienced & Specialized | General Labor |

| Price | Competitive Value | Lowest Price |

| Risk of Defects | Low | High |

Choosing a supplier from Zhejiang or Jiangsu is the first step in securing a reliable supply chain. It's the foundation upon which quality is built.

What quality standards should a top manufacturer meet?

Are you tired of inconsistent valve quality in your shipments? This uncertainty can damage your brand. Let me show you the key standards that separate the professionals from the amateurs.

A top manufacturer must prove its quality with certifications like ISO 9001 or IATF 16949. They should use premium materials like EPDM rubber2 and 62# brass. They must also have strict internal testing for air leakage, pull-out strength, and ozone resistance.

When a customer like Peter places an order, he's not just buying a product. He's buying my promise of quality. That promise is backed by strict standards and relentless testing. Here’s what you should look for.

Essential Certifications

Certifications are not just pieces of paper. They show that a factory has a system for maintaining quality. ISO 9001 is the basic standard for quality management. But for automotive parts, IATF 16949 is even better. It's a more demanding standard specific to the automotive industry. When I see a factory is IATF 16949 certified, I know they are serious about their processes. They have procedures for everything, from checking raw materials to the final inspection of the valves before they are packed.

Material Matters

The best-looking valve is useless if it's made from poor materials. Two things are critical: the rubber and the metal. For the rubber, you want EPDM (Ethylene Propylene Diene Monomer). It resists heat, ozone, and weather much better than cheaper natural rubber, which can crack and cause slow leaks. For the metal stem, we use high-quality brass, typically 62# grade. It's strong and resists corrosion. Some cheaper valves use lower-grade brass or even zinc alloys, which can break or corrode quickly, especially in coastal areas like those in South Africa.

Key Quality Tests

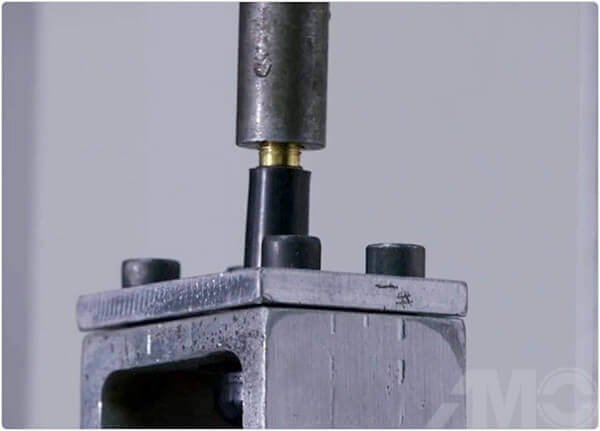

A good manufacturer doesn't just hope their products are good; they test them.

| Test Type | Purpose | Why It's Important |

|---|---|---|

| 100% Air Leakage Test | Checks every single valve for leaks. | This is the most critical test. A leaking valve is a complete failure. |

| Pull-Out Strength Test3 | Measures the force needed to pull the rubber from the metal stem. | Ensures the valve is robust and won't fail under pressure or stress. |

| Ozone Resistance Test4 | Exposes the rubber to high ozone levels. | Simulates aging to ensure the rubber won't crack over time. |

| Salt Spray Test5 | Checks the metal's resistance to corrosion. | Crucial for vehicles in coastal or winter climates where salt is present. |

Asking a potential supplier about these specific tests tells them you are a serious, detail-oriented buyer.

How can you verify a manufacturer's claims?

Every factory's website looks perfect and professional. But how can you be sure the reality matches the marketing? I'll give you simple steps to verify their claims yourself.

You must verify a manufacturer's claims before placing a large order. Always start by requesting samples to test. Then, ask for copies of their certifications and do a quick online check. Finally, request a live video factory tour to see their operations.

Trust is important in business, but in manufacturing, you must always verify. I encourage my clients to be skeptical and to check everything. A good supplier will have nothing to hide. In fact, we welcome the questions because it shows the customer is serious about quality, just like us. Here is the simple process I recommend to all my partners.

Step 1: The Sample Test

Never place a bulk order based on photos alone. Ask for samples. When you get them, don't just look at them. Test them if you can. Check the quality of the rubber. Look at the finish on the metal. If you have the equipment, test the air-holding capability. Compare it to a valve you know is good. I always send samples to new clients. It's the most honest way to show the quality of our work. The product should speak for itself.

Step 2: Document Verification

If a factory claims to be ISO 9001 certified, ask for the certificate. It should have a certificate number and the name of the issuing body. You can often verify this online. This simple check can expose factories that are making false claims. Also, ask for material specification sheets. A professional manufacturer will have detailed documents for the brass and EPDM rubber2 they use. If they hesitate or can't provide these, it's a major red flag.

Step 3: The Virtual Factory Tour

In the past, you had to fly to China to see a factory. Now, it's much easier. Ask for a live video tour using a service like WhatsApp or Zoom. Don't accept a pre-recorded video. On a live call, you can ask them to show you specific things. Ask to see the raw materials storage. Ask to see the production line running. Most importantly, ask to see their quality control station and their testing lab. Seeing the equipment and the workers in action gives you a real feel for their professionalism and capabilities. It’s a powerful tool for verification.

What makes a manufacturer a true partner?

Getting a low price feels like a win. But a difficult supplier can create constant problems. I'll explain how to find a real partner who helps your business succeed.

A true partner offers more than just a product. They provide flexible order quantities6, expert technical support, and responsive communication7. They work with you to solve your specific problems, rather than just trying to sell you what they have in stock.

Over the years, I've learned that the most successful business comes from strong relationships. My client Peter in South Africa has been with me for over 10 years. He doesn't see me as just another supplier from China. He sees me as part of his team. This is because we built a partnership, not just a series of transactions.

Beyond the Price Tag

The initial focus for many importers is price. But a partner looks at your total cost. A cheap valve that fails costs you much more in returns and reputation than a quality valve. A partner understands this. They focus on providing the best value. This includes a reliable product that you never have to worry about. It also includes consistent pricing and clear communication about any potential cost changes.

Communication is Key

A simple supplier might take days to answer an email. A partner responds quickly and clearly. They have English-speaking staff who understand your questions. When there is a problem, maybe a shipping delay or a documentation issue, a partner informs you immediately and works with you to find a solution. They don't disappear or make excuses. Clear, honest communication is the foundation of a good partnership.

Flexibility for Your Business

Many buyers, like Peter, need a variety of items but not a huge quantity of each one. Large factories often have very high Minimum Order Quantities (MOQs) for each item. This is a huge pain point. A true partner is more flexible. At my company, we understand this need. We often help clients by combining several smaller orders into one shipment. This flexibility helps our clients manage their inventory and cash flow better.

Supplier vs. Partner

| Aspect | A Simple Supplier | A True Partner |

|---|---|---|

| Focus | The transaction, lowest price. | The relationship, best value. |

| Communication | Slow and reactive. | Fast, clear, and proactive. |

| Flexibility | Rigid MOQs and policies. | Willing to find solutions for your needs. |

| Goal | To sell you a product today. | To help your business grow for years. |

Finding a manufacturer who acts like a partner is the ultimate goal. They will save you time, reduce your stress, and contribute directly to your success.

Conclusion

Finding top Chinese tire valve makers means looking in Zhejiang, verifying quality through tests and tours, and seeking a flexible partner who understands your business needs.

Explore how industrial clusters enhance manufacturing efficiency and quality through proximity to suppliers and skilled labor. ↩

Learn about the advantages of EPDM rubber, including its resistance to heat, ozone, and weather conditions. ↩

This test ensures the durability and reliability of tire valves under pressure, preventing failures. ↩

This test simulates aging and ensures the rubber won't crack over time, maintaining valve integrity. ↩

This test checks metal resistance to corrosion, crucial for vehicles in harsh environments. ↩

Flexibility in order quantities can help manage inventory and cash flow, especially for smaller businesses. ↩

Effective communication ensures timely problem-solving and builds trust between suppliers and buyers. ↩