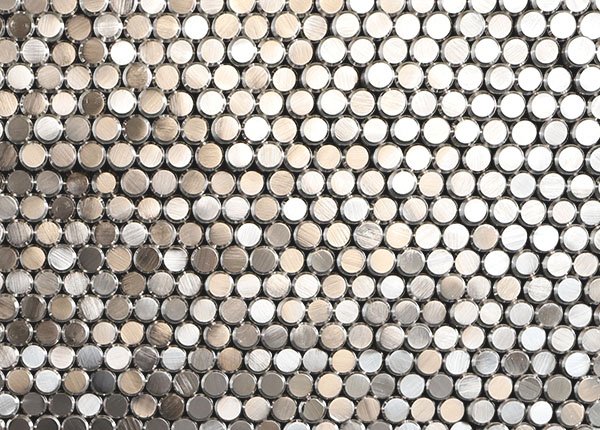

AMO only accept the high-quality brass & EPDM rubber that pass the AMO internal standard tests

All the AMO metalwork according to the principles as bellow

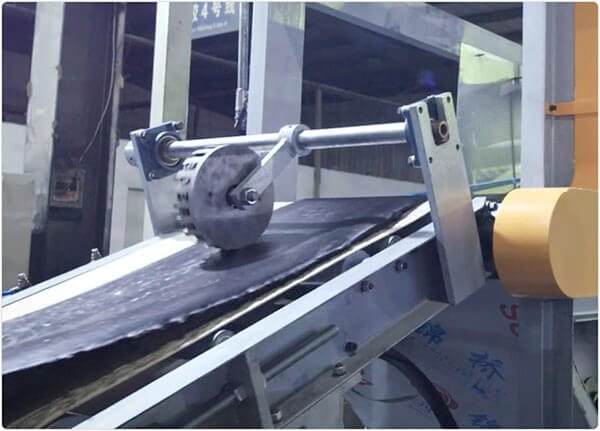

Rubber mixing is the most important step in the whole process, which determines the reliability of the valve. AMO family develop & adopt exclusive formula to strengthen the valve performance

Combine metal with rubber in the imported vulcanizing machine. Though accuracy controls the temperature & time, we can get the satisfying overall valve.

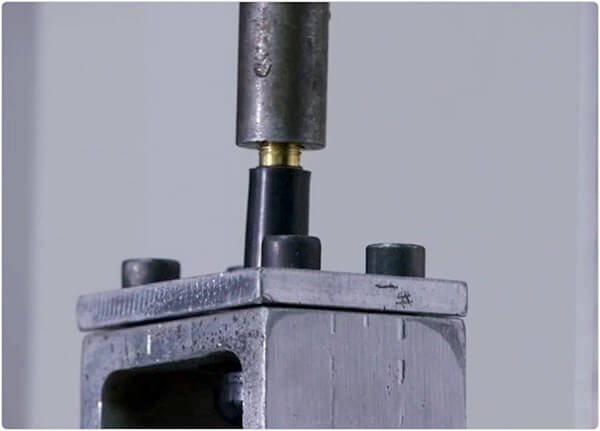

We have high-end auto core & cap assembly machines, Making the valve cores & caps assembly more accurate, guaranteeing the expected torque value in all parts of the valve.

All finished valves will be inspected by experienced workers according to our line to ensure all the functions satisfying your order.

We will then package the valves carefully in designated packaging to prevent them from shocking during delivery.

AMO specialist will contact you within 1 working day, please pay attention to the email with the suffix “@amoautoparts.com”.

Your information will be kept strictly confidential