Tire Valve Manufacturer In China

One-Stop Solutions

Your Trusted Source For Tire Valves, Tube Valves, TPMS Valves, Metal Valves, Presta Valves, And OTR Valves

Helping You Expand Your Tire Valve Catalog

Series for Seletion

0

+

Items Available

0

+

Markets Served

0

+

Select Your Tire Valves now!

Tell us your specifications, We can offer any tire valves for your market!

OEM&ODM?

Have an Idea? We'll Handle the Rest!

From sketch to final production, our expert team works with you to transform the simplest concept into a high-quality, market-ready product!

How AMO Manufacture

AMO factory employs around 50 talents in the tire valve industry to manufacture the safest & reliable valves with SOP

Raw Material Preparing

AMO only accept the high-quality brass & EPDM rubber that pass the AMO internal standard tests

- Confirmation of product design & specs

- Tensile test

- Rigidity test

- Surface quality test

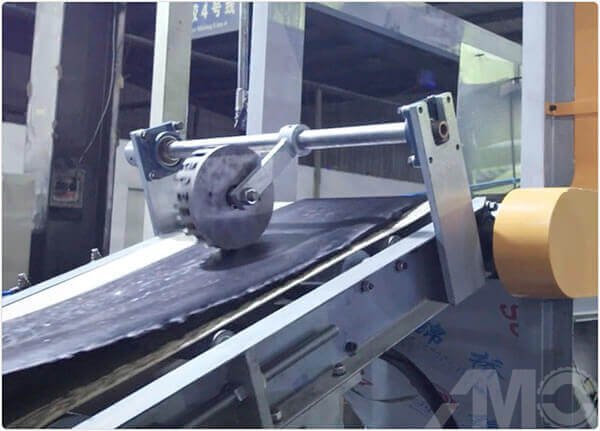

Rubber Mixing

Rubber mixing is the most important step in the whole process, which determines the reliability of the valve. AMO family develop & adopt exclusive formula to strengthen the valve performance

- High tensile force

- Excellent surface gloss

- Outstanding adhesive performance

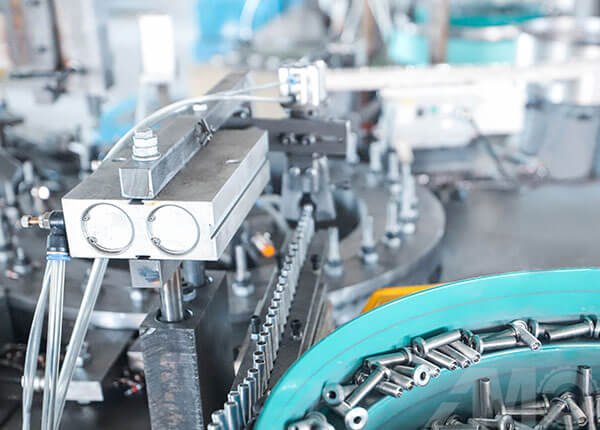

Assembly

We have high-end auto core & cap assembly machines, Making the valve cores & caps assembly more accurate, guaranteeing the expected torque value in all parts of the valve.

Experience

0

Y+

Staff Members

0

+

Total Clients

0

+

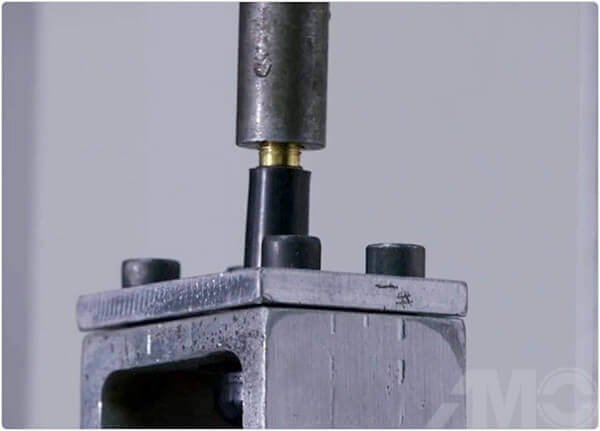

Quality Control In Every Aspect & Every Step

Inspection and measurement disciplines are embedding throughout our processes

Incoming Inspection

Raw material specifications and inspection programs with precisely defined parameters and approved criteria are the golden rule for all brass & rubber raw materials going as valve components.

The main checking methods are shown as below:

- Spec testing

- Hardness testing

- Composition testing

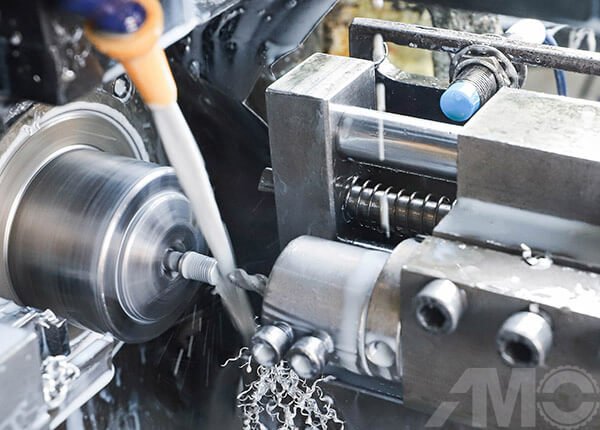

Process Quality Control

Process quality control is carried out with all major machines by employing control documentation exercised at every process. The regular inspection practices are shown as below:

- Structure testing

- Thread testing

- Pull force testing

- Hardness testing

- Viscosity testing

- Ageing testing

- 100% Air-tightness testing

Finished Valve Testing

Valves are subjected to final tests for verifying compliance with international TUV standards and customer’s specific requirements. Customers will have our test certificates for reassuring them of the product quality.

Why Work With AMO

100% OEM service, from material to product design to packaging, you can have all the possibilities with AMO

Experienced Sales

Expect our professional sales to help you understand your needs and recommend the best products possible to your business

Well Trained Workers

Every worker at AMO Factory are well trained to push your project to succeed as expected

Advance Equipments

AMO Factory bring in advance equipments, including production machines and inspection equipment to assure the quality

Low MOQ

Our service starts at as few as 100 pcs to fit your needs

Efficient Communication

All of your inquiries will be answered within 12 hours, be it before-sales or after-sales

Fast Delivery

Your order can be expected to fulfil in 7~30 days on average

Join the community who trust AMO

We’ve worked with AMO AutoParts over 13years, and place over 3 orders per year from Jason since 2012. Their quality is very good and we never met any customer complaint during these years. For valve, the safety is the most important thing, we are very proud with the quality. I like work with Jason

They did nice work and the products look great! All the valves and kits they manufacture have passed our test,I think we will purchase more items from them in the following season.

This is a quick, effective team that really cares for their success. AMO Factory transformed our idea into reality with gorgeous packaging and good quality, which has boost our sales from a year ago.

Up to date, it has been a pleasure cooperating with AMO AutoParts. After 3 problematic years with rubber valve made by other factories, we finally found AMO Factory. It has been a pleasure cooperating with them due to their professional technical and good services.

Message us to get free samples!

Contact us to get a free quote and more expertise about tire valves. Your project will meet the right solution with AMO auto parts.